Software We provide

HPDC

Hpdc analyisi: In HPDC analysis, the PQ2 graph is used to calculate machine setting parameters and die design parameters. This allows you to simultaneously evaluate and optimize the process, ensuring efficient operation and high-quality output.

PQ2Analysis

Pq2 analysis: In PQ2 analysis, you can check the compatibility between calculated die design parameters and HPDC machine parameters. The graph and table forms allow you to identify suitable die and machine parameters for your casting application. This ensures the process is optimized for efficient operation and high-quality results.

Degassing

N2 Degassing: In degassing software, you can validate your N2 degassing variables such as N2 flow, degassing ladle capacity, rotor RPM, metal temperature, and rotor diameter. The software helps you determine the required degassing time and assess the quality of the degassing process

Process Validation

Process validation: In process validation software, you can revalidate your HPDC process to troubleshoot casting defects. The software helps you identify which HPDC machine parameters and die design parameters need to be adjusted to correct the issues and improve casting quality.

Plunger Speed Vs Valve Round

Plunger speed Vs valve round: In plunger speed vs. valve round software, you can create a unique diagram for each HPDC machine and die. This diagram helps determine the precise valve round settings needed to achieve the desired plunger speed, ensuring optimal performance for each specific setup.

Filling Time Calculation

filling time calculation: In filling time software, you can calculate the desired casting filling time by selecting the required constants. This calculated filling time is then used in further analysis to optimize the casting process.

Hydraulic Cylinder Calculation

hydraulic cylinder calculation: In hydraulic cylinder calculation software, you can select the right size of the hydraulic cylinder for the slide movement operation in the die. This ensures efficient and precise movement, optimizing the die casting process.

Finger Cam Calculation

fingle cam calculation: In finger cam calculation software, you can calculate the correct size of the finger cam needed to move the mechanical slide in the die. This ensures accurate and efficient slide movement, optimizing the die casting process.

Flash Predictor

Flash predictor: In flash predictor software, you can determine whether your die will experience flash, indicating molten metal escaping during injection. If flash is predicted, the software can identify potential areas where the die might flash and provide insights to correct these issues during the die design phase, ensuring efficient and defect-free production.

Machine Hour Rate

HPDC Machine Hour Rate:A dedicated tool for high-pressure die casting (HPDC) units to accurately calculate the machine operating cost per hour. It includes all key cost factors—power, consumables, manpower, utilities, melting, and metal holding costs—helping die casters understand true machine costs and identify cost-saving opportunities.

Casting Cost Calculator

A smart tool designed for high-pressure die casting manufacturers to accurately calculate casting costs. It considers all key variables—machine and die depreciation, setup time, machine hour rate, rejection rate, and more—to help die casters understand true production costs and improve profitability.

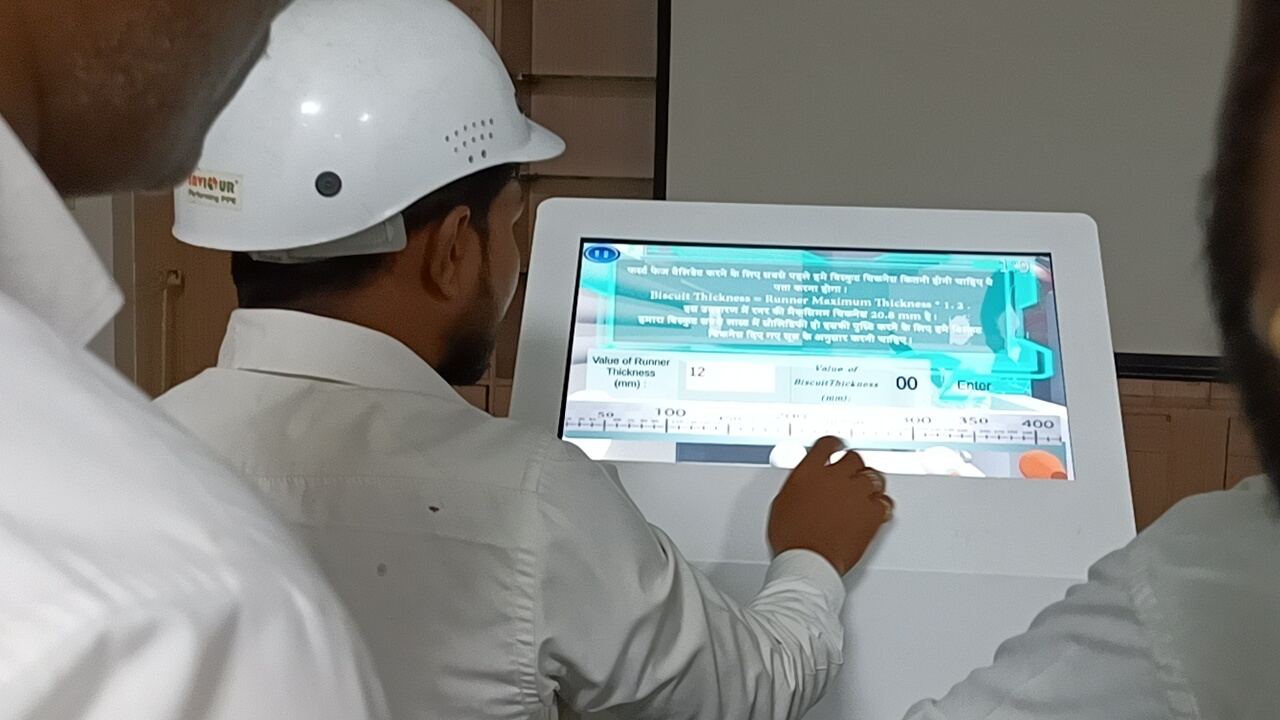

HPDC Pathshala – HPDC Dojo 2.0

The HPDC VR

Who We Are

HPDC Pathshala designed to provide in-depth learning materials on various aspects of HPDC. Our platform is specifically tailored for those involved in the die casting industry, from engineers and technicians to managers and CEOs.

We cover a wide range of topics essential for mastering HPDC, including:

Our platform is specifically tailored for those involved in the die casting industry, from engineers and technicians to managers and CEOs.

- HPDC machine operations.

- Die casting defects and their solutions.

- HPDC process optimization.

- HPDC die design principles.

- Aluminum melting processes.

Defect Troubleshooting

One of the standout features of HPDC Pathshala is our defect troubleshooting sectsoftwareion.

This section provides a thorough guide to identifying and correcting common defects such as porosity, cold shuts, and shrinkage. With step-by-step instructions, users can quickly diagnose issues and implement effective solutions.

Community and Networking

HPDC Pathshala includes a vibrant community section where users can connect with other professionals in the industry.This feature allows for:

- Knowledge Sharing.

- Networking and Collaboration.

- Helping users to learn from each other's experiences and stay updated on industry trends.

Our Commitment

At HPDC Pathshala, we are committed to delivering the highest quality educational content and practical tools to our users.

We believe that continuous learning and improvement are key to success in the HPDC industry. Our resources are designed to support consistent quality control, enhance efficiency and speed, and facilitate ease of use across all levels of experience.